- #Iso 2768 hole tolerance it6 iso

- #Iso 2768 hole tolerance it6 plus

#Iso 2768 hole tolerance it6 iso

Selection of suitable fits of machine parts according to the international standard ISO 286. Using this tool the following tasks can be solved: Tolerances and fits This book includes tables and calculations for easy option of fits of machine parts and determination of their dimensional tolerances and deviations. IT18) can be used for prescriptions of hole tolerance zones by their mutual combinations, in practice only a limited range of tolerance zones is used. Determination of non-prescribed limit deviations of linear and angular dimensions according to ISO 2768. Field of use of individual tolerances of the system ISO: IT01 to IT6 For production of gauges and measuring instruments IT5 to IT12 IT11 to IT16 IT16 to. List of standards: ANSI B4.1, ANSI B4.2, ISO 286, ISO 1829, ISO 2768, EN 20286, JIS B 0401 Information on the syntax and control of the calculation can. Find range button- Automatically find the appropriate range in the reference table window Calculate button- Apply selected tolerances to the basic dimension- Results are displayed below the. Center text field- Basic dimension to which tolerances will be applied. Decimal precision selection 3, 4, 5- Number of digits after the decimal point for all dimension. The inch selection is for convenience only. Find appropriate range Click find range button or step through the ranges using next and previous range button in the reference table windowselect Hole and Shaft class using radio buttons to the left and right in. Enter basic dimension into the top most text field. Selection of the tolerances displayed in the reference table Basic usage flow. Filter for the tolerances displayed in the table window. The calculator application page is divided into 3 windows.Ĭalculator window. Note: Hole based fits should be preferred. A feature tolerance is defined by the basic size followed by the tolerance designation. Upper case letters apply to holes or female type features. The letter is the tolerance deviation, the number the tolerance grade. A tolerance is described using a letter followed by a number. General overview (all dimensions are millimeters)The basic size of the feature or fit is the dimension the tolerances will be applied to: The zero line in the calculator. British Standard for metric Limits and Fits. Tolerances can be applied to holes and shafts as well as other shapes. These dimensions are standardized limits for assemblies of mechanical component. ISO metric tolerance zone limits and fits.ĭescription. ABC Tribology- Tables of ISO limits This Page is being developed. Note: The tolerance band T is an absolute length value it does not have a negative value. Hole and Shaft tolerance tables- Using Fundamental Deviations and Tolerance Band T Examples in using above tables. Example: a 20mm Round h9 will have a tolerance of + 0mm, - 0.052mm which. #Iso 2768 hole tolerance it6 plus

ISO 286-2 Round Bar Tolerances Tolerances are all plus 0mm, - mm size. The ISO System of Limits and Fits is a coordinated system of hole and shaft. The ISO System of Limits and Fits - Tolerances and Deviations. Hole chart and shaft chart for ISO tolerance and limit and fit. ISO Tolerances for Holes(ISO 286-2)- 3mm to 400 mm. The need for tolerances to be identified on drawings is vital to allow assembly of parts in the desired. Tables of standard tolerance grades and limit deviations for holes and shafts Notes The tolerance of size is normally defined as the difference between the upper and lower dimensions. Bases of tolerances, deviations and fits. Index of ISO Hole and Shaft tolerances/limits pages. ROYMECHX clone of ROYMECHClick arrows to page adverts. Index of ISO Hole and Shaft tolerances/limits pages Disclaimer: The information on this page.

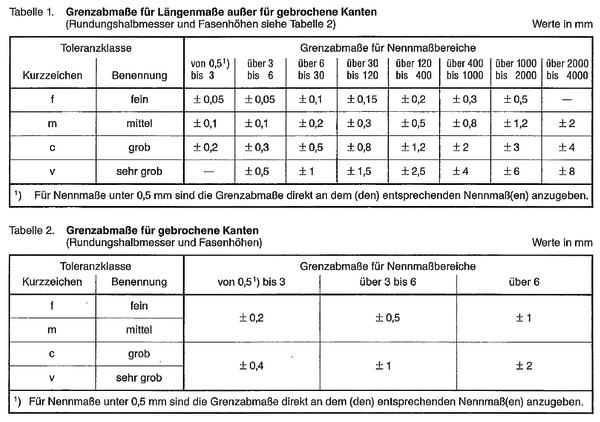

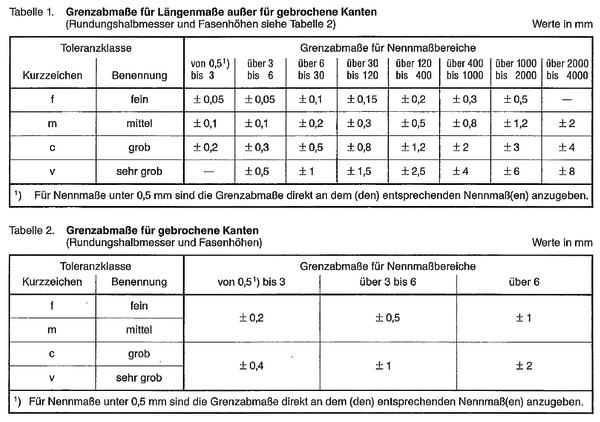

General tolerances for linear and angular dimensions according to ISO 2768. ISO Tolerance System,Limits And Fits,Engineering standards, Iso Tolerance,ISO286,ANSI,ISO tolerance system,Limits and Fits,hole.

ISO 2768 and derivative geometrical tolerance. The following are general geometrical tolerances per.

0 kommentar(er)

0 kommentar(er)